Automatic sampler for cereals, feedstuffs, seeds and similar bulk flow solids

Benefits:

- 100% representative sample, thereby maximising control.

- Optimum productivity - the possibility of error in sample taking is

eliminated as sampling is automatic

- Rapid payback period, with the benefit of continued improved

contributions thereafter.

- Reliable, maintenance free construction.

- In addition to cereals will sample feedstuff, seeds, rice, soybeans,

milled products - in fact most bulk flow solid.

- Remote control facility.

Operation:

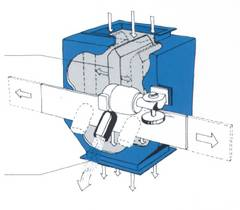

Sampling is effected by means of a diverter with an open slot in the leading edge. The diverter is moved automatically through the stream (e.g. grain), see principal sketch. Thus a correct sample is taken from across the spout area, not just at the side or in the centre of the flow. Test interval is stepless adjustable from 1 test per 5 seconds to 1 test per hour. A remote control facility also exists whereby it is possible to switch on the sampler from a central control room; alternatively to let it operate on elevator control.

Capacities:

Size of the single sample will depend on the spout flow rate and the size of the slot in the diverter. The standard slot is 8 mm. Other openings (2, 3, 4, 5, 6, 7, 8, 10, 12, 14, 16, 18, 20 mm) can be supplied on request. The slot can easily be changed on site.

Specification

The housing consits of rilsan covered steel plate. All other metal components are electrogalvanised.

Electric equipment with gear motor, limit switch and control panel including motor protecting relay and timer.

Power Supply: 3 phase 400 V, 50 Hz. Optional: 3 phase 230 V, 50 Hz.

The sampler must be installed in a vertical spout. Maximum permissible deviation from the vertical is 25°.

Flange for model 200 DVB is 200 x 200 mm. Flange for model 300 DVB is 300 x 300 mm.

Flange are pre-bored for bold assembly; flanges are included

Adapters for other Inlets/Outlets available (see b.m.).